Downhole Probes

Together with our sister company Mount Sopris ALT offers a wide range of downhole probes to the industry. Our tools are designed to standup to the harshest borehole environments and present a reliable partner for the logging operator.

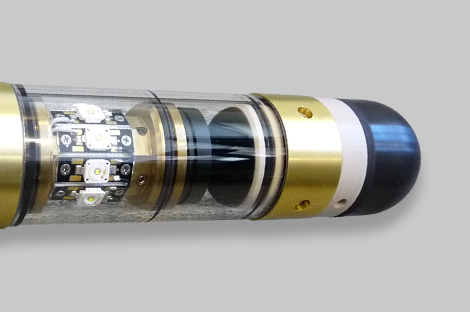

The Quick Link (QL) series of downhole logging probes convinces by its fast telemetry and flexibility. Probe subs can be combined in custom configurations to acquire more data in a single logging pass. Each QL sub can be used as a stand-alone probe or combined into a tool stack to yield multiple measurement parameters simultaneously.

QL40 | probe line

The QL40 probe line is designed specifically for slimhole geophysical applications.With tool diameters between 40mm – 50mm (1.6” – 2”) all tools are rated to temperatures of 70°C (158°F) and withstand pressures of 200 bar (2900 psi).

QL43 | probe line

The QL43 probe line has been designed to stand up against higher temperatures and pressures.With diameters of only 43mm (1 11/16”) the probes are available rated to 125°C (257°F) and 170°C (338°F) and withstand pressures of 700 bar (10160 psi).

Ultrasonic televiewer, natural gamma, casing collar locator and deviation probes complement each other in the QL 43 probe line.

QL85 | probe

The QL85 has been designed for high temperature / high pressure geothermal applications in cooperation with Sandia National Laboratories.With tool diameters of 85mm (3 3/8”) the tool stands up against temperatures of 300°C (572°F) at pressures exceeding 1400 bar (20305 psi).